Views: 0 Author: Site Editor Publish Time: 2025-09-08 Origin: Site

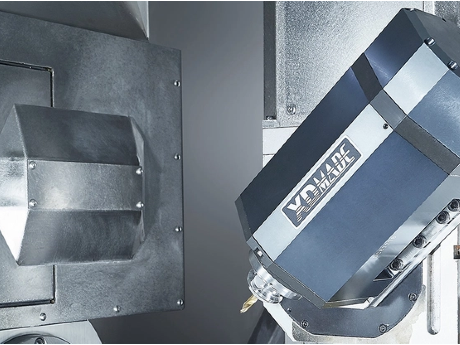

Servo turrets are a key innovation in the world of CNC machining, especially when integrated with 5-axis turning milling machines. These turrets provide manufacturers with unparalleled flexibility, allowing for rapid tool changes and a wide range of machining operations. By incorporating servo-driven turrets into 5-axis turning milling machines, manufacturers can significantly reduce downtime, improve precision, and optimize production processes. This integration not only enhances the overall machining efficiency but also allows for more complex, multi-tasking operations to be performed with a single machine setup. The combination of servo turrets and 5-axis capabilities opens up a new world of possibilities for manufacturers, improving the speed and versatility of machining across a variety of industries, including aerospace, automotive, and precision engineering.

One of the key advantages of servo turrets in 5-axis turning milling machines is the enhanced tooling flexibility they provide.

Automatic Tool Changes: Servo turrets are designed to automate the tool-changing process, which dramatically reduces downtime during production. In traditional CNC machines, changing tools can be a time-consuming task, requiring operators to stop the machine and manually replace the tools. However, with a servo turret, the tool change is automated, enabling the machine to swiftly transition between different tools without the need for manual intervention. This not only boosts productivity but also ensures that production can continue without interruption, reducing idle time and increasing overall efficiency.

Tool Variety: Another significant benefit of servo turrets is their ability to handle a wide variety of tools for different machining processes. Whether it’s turning, drilling, milling, or tapping, the servo turret is capable of holding a range of tool types, all within a single machine. This flexibility allows manufacturers to perform a multitude of tasks without needing to change setups or switch between different machines. The result is a more streamlined workflow that reduces setup times, minimizes the risk of errors, and enhances production efficiency.

By enabling the use of a diverse range of tools, servo turrets in 5-axis turning milling machines provide manufacturers with greater freedom in the types of parts they can produce, making it easier to handle both simple and highly complex parts.

Precision is at the heart of every machining operation, and servo turrets are designed to enhance the accuracy and consistency of machining processes in 5-axis turning milling machines.

Accuracy: Servo turrets are equipped with advanced drive systems that allow for precise and repeatable tool positioning. The high degree of control offered by these turrets ensures that each tool is positioned exactly where it’s needed, with minimal deviation. This level of accuracy is crucial for industries such as aerospace and medical manufacturing, where even the smallest misalignment can compromise the integrity of the component. By ensuring precise tool positioning, servo turrets contribute to the overall accuracy of the machining process, helping to produce parts that meet the strictest tolerances.

Reducing Tool Wear: One of the challenges in any machining process is minimizing tool wear, which can lead to reduced performance and the need for more frequent tool replacements. Servo turrets help address this issue by providing precise tool handling and reducing unnecessary tool movement. The precision in positioning and movement helps minimize excessive wear on the tools, leading to longer tool life and fewer tool changes. In turn, this reduces production costs, as the need for frequent tool replacements and maintenance is minimized. Longer tool life also translates to more consistent part quality, as the tools maintain their sharpness and cutting performance for longer periods.

Speed and efficiency are critical factors in any manufacturing process, and servo turrets enhance both in 5-axis turning milling machines.

Faster Cycle Times: The automation provided by servo turrets significantly accelerates production cycles. By automating tool changes and reducing the need for manual intervention, these turrets enable faster cycle times. The ability to quickly switch between tools means that different machining processes can be performed in rapid succession, which speeds up the overall production process. For manufacturers producing high volumes of parts, the ability to shorten cycle times can have a major impact on overall productivity, enabling them to meet tight deadlines and reduce production costs.

Reduced Setup Time: Traditional machining processes often require extensive setup time, as parts need to be repositioned and tools need to be changed between different operations. However, with a servo turret, the need for frequent repositioning and tool changes is eliminated. This streamlined operation reduces the time spent on setup, allowing manufacturers to complete tasks more quickly and efficiently. Shorter setup times translate directly into faster production cycles, which can increase the overall throughput of a manufacturing facility and reduce lead times.

As the speed and efficiency of machining processes improve, manufacturers can take on more projects, produce higher quantities of parts, and lower their production costs—all without sacrificing quality.

One of the standout features of servo turrets in 5-axis turning milling machines is their ability to handle multi-process machining in a single setup.

Multi-Tasking Capability: Servo turrets enable 5-axis turning milling machines to perform multiple operations—such as drilling, milling, and turning—within a single machine cycle. This eliminates the need for multiple machines or machine setups, saving valuable time and reducing the complexity of the production process. Whether machining a part that requires multiple steps or a part that needs to be worked on from various angles, the servo turret allows the machine to handle all of these operations without interruption. This multi-tasking capability significantly improves workflow efficiency and reduces the number of machine transitions needed to complete a part.

Handling Complex Parts: Servo turrets are particularly beneficial when it comes to machining complex parts that require a range of operations. Many high-precision components, such as turbine blades, gears, and medical implants, require machining from multiple sides and angles. In the past, this might have involved multiple setups or even different machines. However, the integration of servo turrets with 5-axis turning milling machines allows for all of these processes to be performed in a single setup, improving efficiency and accuracy. The ability to perform all necessary machining operations on complex parts without having to change setups or machines is a major advantage for manufacturers producing intricate, high-precision components.

Servo turrets are a crucial element in enhancing the flexibility, speed, and precision of 5-axis turning milling machines. By enabling automatic tool changes, improving machining accuracy, and facilitating multi-tasking operations, these turrets significantly elevate machine performance. Manufacturers benefit from faster cycle times, reduced setup times, and the ability to perform complex machining tasks in a single setup. This versatility is especially valuable for industries like aerospace, automotive, and precision engineering, where efficiency and flexibility are paramount.

As machining demands continue to advance, the role of servo turrets will remain essential in modern manufacturing. By allowing manufacturers to produce increasingly intricate and high-performance parts, servo turrets optimize machining processes, making them indispensable in today’s competitive landscape.

To discover how servo turrets in 5-axis turning milling machines can enhance your production capabilities, Daying Xindai Machinery Manufacturing Co., Ltd. offers state-of-the-art solutions designed to meet the highest industry standards. Their expertise and advanced machinery can help streamline your operations and improve efficiency. To learn more or to inquire about customized solutions, visit Daying Xindai’s website or contact their team for further assistance.