Views: 0 Author: Site Editor Publish Time: 2025-08-29 Origin: Site

The mold-making industry plays a pivotal role in the production of parts for various sectors, including automotive, aerospace, and consumer goods. It demands high precision, speed, and the capability to handle intricate designs, all while ensuring cost-efficiency and minimal waste. The rise of advanced machining technologies, particularly 5-axis turning milling machines combined with servo turrets, has revolutionized this industry. These cutting-edge solutions allow mold makers to produce highly complex molds faster, with better surface finishes, and at lower costs. The integration of these technologies is helping businesses meet the increasing demand for more precise, versatile, and efficient mold-making processes.

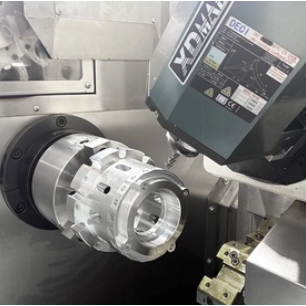

Precision is paramount in the mold-making industry, as even the smallest deviation from design specifications can lead to defects in the final product. Mold makers are often tasked with producing intricate and detailed molds that require superior accuracy. This is where 5-axis turning milling machines prove invaluable.

Complex Mold Designs: One of the major challenges in mold making is producing molds with complex geometries and fine details. Traditional machining methods often struggle to handle these intricate designs, requiring multiple setups and time-consuming manual adjustments. However, 5-axis turning milling machines excel at machining parts with multiple angles and contours in a single setup. The ability to simultaneously control the machine along five axes allows for highly detailed and intricate mold features, such as undercuts, deep cavities, and curved surfaces. This capability drastically reduces the need for rework and allows for the creation of more advanced molds that meet the increasingly complex demands of modern manufacturing.

Improved Surface Finish: Another significant advantage of 5-axis turning milling machines is their ability to achieve smoother surface finishes, which is crucial for mold-making. Molds with rough surfaces can result in poor product quality, especially in industries where aesthetic appeal and functional performance are critical. The precision of 5-axis machining ensures that the surface finish is significantly improved, with fewer manual polishing or finishing steps required. This not only enhances the overall quality of the molds but also reduces production time, as fewer secondary operations are needed to achieve the desired finish.

In today’s competitive manufacturing landscape, speed is just as important as precision. Mold makers need to complete projects faster to meet customer deadlines and stay competitive. 5-axis turning milling machines, combined with servo turrets, help achieve faster production times without sacrificing quality.

Reduced Setup Time: One of the most significant advantages of using 5-axis machines in mold making is the reduction in setup time. Traditional machining often requires multiple setups for different sides of the mold or for using different tooling, leading to delays and increased costs. 5-axis turning milling machines, however, can perform operations on all sides of the mold in a single setup. This eliminates the need for several machine tool changes or repositioning, which can be time-consuming and costly. By reducing the number of setups, the production process is streamlined, allowing mold makers to complete more jobs in less time.

Quicker Turnaround: The integration of 5-axis turning milling machines with servo turrets also contributes to faster turnaround times. These machines offer a high level of automation, enabling continuous, high-speed production without constant human intervention. When combined with advanced tool paths, servo turrets can automatically change tools based on the specific requirements of the mold being produced, which further shortens the production cycle. The ability to maintain high speeds while ensuring precision helps mold makers deliver high-quality products within tight timeframes, which is especially beneficial in industries where quick delivery is a competitive edge.

Servo turrets offer an added level of flexibility and automation, which enhances the overall functionality of 5-axis turning milling machines. In mold making, having a diverse range of tooling options is critical for achieving different machining tasks.

Integration with Servo Turrets: Servo turrets are highly effective at providing flexibility in tooling. These turrets allow mold makers to switch between various cutting tools quickly and efficiently, without the need for manual intervention. The servo-controlled mechanism ensures precise and accurate tool positioning, allowing for more consistent results. This flexibility is especially valuable in mold making, where molds often require different types of cuts, drills, and finishes depending on their design. With servo turrets, mold makers can handle a wide range of tooling options, improving the versatility of the machine and reducing the need for multiple machines or operators.

Automation in Tooling Changes: One of the most significant benefits of servo turrets is their ability to automate the tool-changing process. In traditional machining, tool changes are often manual, which can be time-consuming and prone to errors. However, servo turrets streamline this process by automatically selecting and replacing tools as needed, based on pre-programmed instructions. This not only saves valuable production time but also reduces human error, ensuring consistent tooling performance across multiple jobs. The automation of tooling changes further increases the overall efficiency of the mold-making process, leading to faster turnaround times and higher-quality molds.

In mold making, minimizing material waste and achieving high accuracy are key to maximizing profitability. 5-axis turning milling machines and servo turrets play a crucial role in improving both material efficiency and the overall quality of the molds produced.

Material Efficiency: Traditional mold-making processes often involve multiple cuts and setups, which can lead to significant material wastage. However, 5-axis turning milling machines, with their precise cutting capabilities, ensure that each cut is made with minimal excess material. The advanced tool paths and high accuracy of these machines enable mold makers to optimize material usage, reducing waste and cutting costs. Moreover, the ability to work with a wide variety of materials, including harder metals, means that mold makers can make better use of expensive raw materials without compromising on quality.

Higher Precision: Precision is a critical factor in mold making, as even slight deviations can lead to defects in the final product. 5-axis turning milling machines, with their ability to work along multiple axes simultaneously, provide the high levels of precision needed to meet the strict tolerances required for mold manufacturing. This precision ensures that each mold is made to exact specifications, reducing the likelihood of defects and rework. Furthermore, the integration of servo turrets helps maintain this precision by automating the tooling process and reducing human error. The result is molds with tighter tolerances, consistent quality, and fewer chances of error or rework.

The integration of 5-axis turning milling machines and servo turrets has revolutionized the mold-making industry by offering exceptional precision, speed, and flexibility. These advanced technologies allow manufacturers to produce intricate, high-quality molds more efficiently, reducing setup times and speeding up production cycles. Enhanced tooling flexibility also enables mold makers to meet the increasing demand for complex designs while controlling costs. Moreover, the precision of these machines reduces material waste and improves accuracy, helping companies maintain the highest quality standards.

For businesses looking to elevate their mold-making capabilities, Daying Xindai Machinery Manufacturing Co., Ltd. offers cutting-edge solutions designed to meet the unique needs of the industry. With their expertise in 5-axis turning milling machines and servo turrets, Daying Xindai ensures that manufacturers can achieve faster production, greater precision, and reduced costs. To explore how Daying Xindai can help optimize your mold-making processes, visit their website or contact their team for a personalized consultation. Their advanced technology and industry knowledge can drive your business towards greater efficiency and innovation.