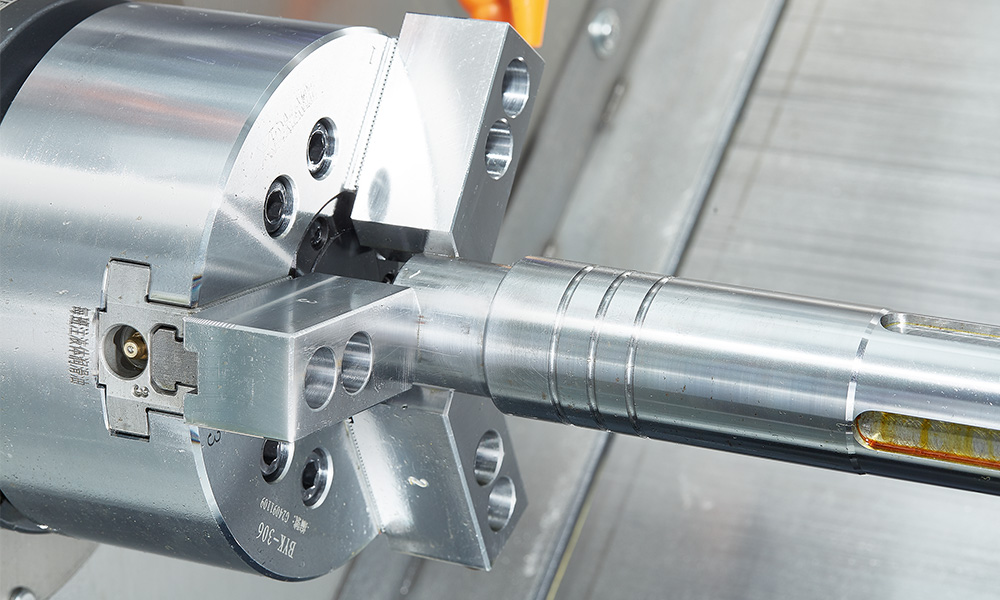

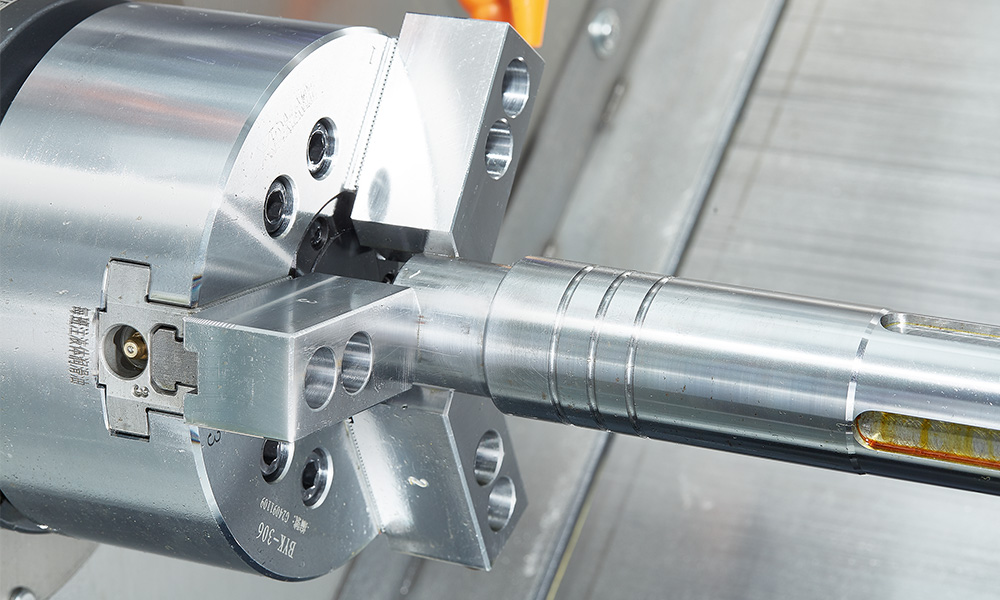

This machine tool has extremely strong machining capacity and machining precision, heavy cutting and high rigidity combination of equipment, the use of tail-top design, can be machined longer workpieces, and can be docked with truss-type manipulator.

The machine tool overall casting bed, bed foot with resin sand casting, aging treatment, the use of ultra-frequency quenching, structural stability, rigidity and reliable.

The machine tool internal protection for the whole mobile internal protection, than the traditional machine tool protection effect to enhance seventy per cent. Effectively block the iron slag, chipping water and debris into the Bie bar guide, better protection of electrical equipment, not only conducive to the protection of the machine tool and clean up, but also extend the service life of the machine tool.

Z-axis adopts Japan's small giant design structure, guideway for the horizontal step-type placement, greatly improving the wear resistance and rigidity of the guideway.

Adopting domestic or imported high rigidity horizontal hydraulic servo turret, high positioning accuracy, fast speed of nearby tool change, small re-cutting deformation.

Adjustable sleeve tailstock design to meet most of the heavy cutting processing.

The optional automatic chip conveyor adopts one-piece streamline modelling, which is beautiful and generous, with smooth chip discharge, small volume, high efficiency, smooth conveyance, safety and reliability, low noise, and overload protection and other functions.

Technical Parameters:

| Item/ Model | Component name and unit | XD-V50K |

| Processing range | Max turning diameter over bed(mm) | Φ500 |

| Max diameter on the pallet(mm) | / | |

| Max machining length(mm) | 480 | |

| Max bar diameter(mm) | Φ51 | |

| Feed | Max X-axis travel(mm) | 580 |

| Max Y-axis travel(mm) | / | |

| Max Z-axis travel(mm) | 550 | |

| X-axis fast movement speed(m/min) | 18 | |

| Z-axis fast movement speed(m/min) | 18 | |

| Repeat positioning accuracy(mm) | ±0.002 | |

| Guide rail form | Linear guide rail | |

| Spindle | Sleeve spindle unit(model) | A2-6 |

| Chuck size(Inch) | 8 | |

| Spindle motor power(KW) | 15 | |

| Max speed(r/min) | 3000 | |

| Spindle through-hole diameter(mm) | Φ66 | |

| Toolpost | Turret form | Servo urret 380 |

| Tool holder specification(mm) | 8 station/32 12 station/25 | |

| Boring tool holder(mm) | 8 station/50 12 station/32 | |

| Adjacent tool changing time(S) | 0.35 | |

| Tailstock | Tailstock sleeve travel(mm) | 80 |

| Tailstock sleeve diameter(mm) | 80 | |

| Tailstock sleeve form(mm) | Hydraulic pressure | |

| Tailstock sleeve taper(Mohs) | 5# | |

| Specification | Machine net weight(KG) | ≈4000 |

| Length * width * height(mm) | 2600*1650*1880 | |

| Other | Optional configuration | Power turret,chip conveyor,truss manipulator,feeder |

| Socpe of application | Large shaft,metal disc |

This machine tool has extremely strong machining capacity and machining precision, heavy cutting and high rigidity combination of equipment, the use of tail-top design, can be machined longer workpieces, and can be docked with truss-type manipulator.

The machine tool overall casting bed, bed foot with resin sand casting, aging treatment, the use of ultra-frequency quenching, structural stability, rigidity and reliable.

The machine tool internal protection for the whole mobile internal protection, than the traditional machine tool protection effect to enhance seventy per cent. Effectively block the iron slag, chipping water and debris into the Bie bar guide, better protection of electrical equipment, not only conducive to the protection of the machine tool and clean up, but also extend the service life of the machine tool.

Z-axis adopts Japan's small giant design structure, guideway for the horizontal step-type placement, greatly improving the wear resistance and rigidity of the guideway.

Adopting domestic or imported high rigidity horizontal hydraulic servo turret, high positioning accuracy, fast speed of nearby tool change, small re-cutting deformation.

Adjustable sleeve tailstock design to meet most of the heavy cutting processing.

The optional automatic chip conveyor adopts one-piece streamline modelling, which is beautiful and generous, with smooth chip discharge, small volume, high efficiency, smooth conveyance, safety and reliability, low noise, and overload protection and other functions.

Technical Parameters:

| Item/ Model | Component name and unit | XD-V50K |

| Processing range | Max turning diameter over bed(mm) | Φ500 |

| Max diameter on the pallet(mm) | / | |

| Max machining length(mm) | 480 | |

| Max bar diameter(mm) | Φ51 | |

| Feed | Max X-axis travel(mm) | 580 |

| Max Y-axis travel(mm) | / | |

| Max Z-axis travel(mm) | 550 | |

| X-axis fast movement speed(m/min) | 18 | |

| Z-axis fast movement speed(m/min) | 18 | |

| Repeat positioning accuracy(mm) | ±0.002 | |

| Guide rail form | Linear guide rail | |

| Spindle | Sleeve spindle unit(model) | A2-6 |

| Chuck size(Inch) | 8 | |

| Spindle motor power(KW) | 15 | |

| Max speed(r/min) | 3000 | |

| Spindle through-hole diameter(mm) | Φ66 | |

| Toolpost | Turret form | Servo urret 380 |

| Tool holder specification(mm) | 8 station/32 12 station/25 | |

| Boring tool holder(mm) | 8 station/50 12 station/32 | |

| Adjacent tool changing time(S) | 0.35 | |

| Tailstock | Tailstock sleeve travel(mm) | 80 |

| Tailstock sleeve diameter(mm) | 80 | |

| Tailstock sleeve form(mm) | Hydraulic pressure | |

| Tailstock sleeve taper(Mohs) | 5# | |

| Specification | Machine net weight(KG) | ≈4000 |

| Length * width * height(mm) | 2600*1650*1880 | |

| Other | Optional configuration | Power turret,chip conveyor,truss manipulator,feeder |

| Socpe of application | Large shaft,metal disc |

| Item/ Model | Component name and unit | XD-V50K |

| Processing range | Max turning diameter over bed(mm) | Φ500 |

| Max diameter on the pallet(mm) | / | |

| Max machining length(mm) | 480 | |

| Max bar diameter(mm) | Φ51 | |

| Feed | Max X-axis travel(mm) | 580 |

| Max Y-axis travel(mm) | / | |

| Max Z-axis travel(mm) | 550 | |

| X-axis fast movement speed(m/min) | 18 | |

| Z-axis fast movement speed(m/min) | 18 | |

| Repeat positioning accuracy(mm) | ±0.002 | |

| Guide rail form | Linear guide rail | |

| Spindle | Sleeve spindle unit(model) | A2-6 |

| Chuck size(Inch) | 8 | |

| Spindle motor power(KW) | 15 | |

| Max speed(r/min) | 3000 | |

| Spindle through-hole diameter(mm) | Φ66 | |

| Toolpost | Turret form | Servo urret 380 |

| Tool holder specification(mm) | 8 station/32 12 station/25 | |

| Boring tool holder(mm) | 8 station/50 12 station/32 | |

| Adjacent tool changing time(S) | 0.35 | |

| Tailstock | Tailstock sleeve travel(mm) | 80 |

| Tailstock sleeve diameter(mm) | 80 | |

| Tailstock sleeve form(mm) | Hydraulic pressure | |

| Tailstock sleeve taper(Mohs) | 5# | |

| Specification | Machine net weight(KG) | ≈4000 |

| Length * width * height(mm) | 2600*1650*1880 | |

| Other | Optional configuration | Power turret,chip conveyor,truss manipulator,feeder |

| Socpe of application | Large shaft,metal disc |

| Item/ Model | Component name and unit | XD-V50K |

| Processing range | Max turning diameter over bed(mm) | Φ500 |

| Max diameter on the pallet(mm) | / | |

| Max machining length(mm) | 480 | |

| Max bar diameter(mm) | Φ51 | |

| Feed | Max X-axis travel(mm) | 580 |

| Max Y-axis travel(mm) | / | |

| Max Z-axis travel(mm) | 550 | |

| X-axis fast movement speed(m/min) | 18 | |

| Z-axis fast movement speed(m/min) | 18 | |

| Repeat positioning accuracy(mm) | ±0.002 | |

| Guide rail form | Linear guide rail | |

| Spindle | Sleeve spindle unit(model) | A2-6 |

| Chuck size(Inch) | 8 | |

| Spindle motor power(KW) | 15 | |

| Max speed(r/min) | 3000 | |

| Spindle through-hole diameter(mm) | Φ66 | |

| Toolpost | Turret form | Servo urret 380 |

| Tool holder specification(mm) | 8 station/32 12 station/25 | |

| Boring tool holder(mm) | 8 station/50 12 station/32 | |

| Adjacent tool changing time(S) | 0.35 | |

| Tailstock | Tailstock sleeve travel(mm) | 80 |

| Tailstock sleeve diameter(mm) | 80 | |

| Tailstock sleeve form(mm) | Hydraulic pressure | |

| Tailstock sleeve taper(Mohs) | 5# | |

| Specification | Machine net weight(KG) | ≈4000 |

| Length * width * height(mm) | 2600*1650*1880 | |

| Other | Optional configuration | Power turret,chip conveyor,truss manipulator,feeder |

| Socpe of application | Large shaft,metal disc |

content is empty!